|

This

is a crank

which after years of faithfull service has had enough. Cracks are

growing

from the sharp corners of the internal square, here visible at 3 and 6

o'clock. Time to order a new crankset, and no heavy sprinting please. |

|

The

accompanying

righthand crank has also suffered: the crankarm is trying to part

company

from the spider. Again a crack has started on a sharp corner in a

heavily

stressed area. |

|

200

engineering

textbooks can't be wrong! This is what happens when you incorporate all

stressraisers known to mankind in a single dynamically loaded part.

Maybe

the designer thought the part wouldn't know where to start failing

first

for all the possibilities! The other side:

Photo's

courtesy

of Bert L:am

|

|

Crack

in the

righthand crank. A notch caused by a dropped chain has nothing to with

it, as demonstrated by the lefthand crank:  |

|

Could

we please

go back to oldfashioned spindles with external flats? Here 's an axle

with

an internal 8mm hexagonal in the threaded end. That doesn't leave much

meat. The result is two cracks originating from the points of the

hexagon,

straight through the threads

Removal

was

a bear, as the force of the allan-key expands the thread! (solved it by

chucking the axle in the lathe) Removal of this kind of pedal on the

chainwheelside is a risky

business anyhow, you won't be the first needing stitches

|

|

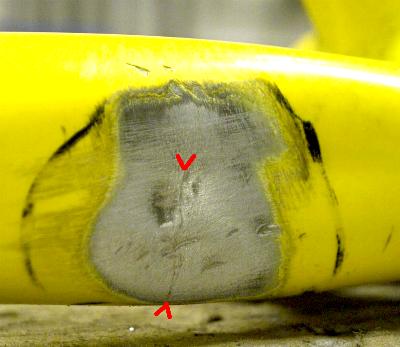

Broken

bracket-axle

from a spinning bike.

A

spinning

bike doesn't see any rain, so the bearings will last indefinitely. This

isn't true for the axle, certainly when the axle meets with a very hard

steel crank. With a steel crank the stresstransition is much more

severe,

and it looks as the axle snapped just where the crankbolt ended.

Spinning bikes can't move from side to side, which must make things

hrder on the crank too.

The

crack clearly

started in the lower half. The continuing motion has polished the

crack-surface

until the remaining section grew so small it failed. The fresh failure

zone is course.

(picture

courtesy

Marten Hoffmann)

|

|

This

is the

shell of an XT rearhub (freehubside) The bearings are well lubricated,

judging by the grease coming out of the crack! The 5 YO hub has done

about

15.000 km's worth of commuting and loaded touring. Crack corresponds

with

the start of the innerflange which is very thick because it has to

support

the freehub. |

|

This

is what

an overloaded QR axle looks like. The previously round hole has

elongated

and the sides show serious necking. It is always a good idea to

lubricate

the skewer, with less friction there is more clamping force available,

and you get a better idea what you're up to |

|

A

handlebar

with severe deformation in the clamping area. In fact the deformation

was

so severe that the bars kept rotating. Excessive tightening, an aero

bar

and a large hole in the barclamp (see the bulge) were probably

contributing

factors.

Replace

at

once! |

|

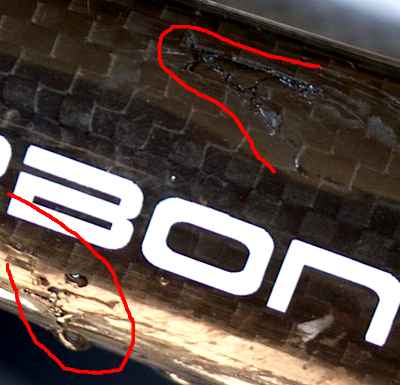

With

a carbon

bar a spill will have far reaching effects. I've never seen a alloy bar

crack here, the norm being that you can at least finish the race |

|

There

are many

ways to stop a bike! See here the downtube-headtube junction in a

filletbrazed

frame which met with a solid object. The downtube sprouts a double chin

(yes, that stubble is cracked clearcoat), and the forkrake suffered a

lot

too. With a new fork this frame is probably good for another few

thousand

miles, but it won't handle like new. And keep your eyes peeled for the

start of a crack in this area. |

|

Expensive

Koga's

are not immune from problems, and the guarantee didn't extend to the

second

owner!

The

crack has

started from the sharp point of the bottom lug. From the rust at the

bottom

section you see it has been awhile and the crack could possible have

been

spotted before total collapse. The crack took some time untill the

remaining

section couldn't handle the strain and snapped.

(picture

courtesy

Niels Alsemgeest)

|

|

The

rivnut

(bottlecage mounting) is being pulled through the frame. Not very

threathening

in this stage, unless the crack starts growing in another direction and

then things will happen fast! |

|

A

waste of

a fresh powdercoat-job. This side is the final crack, the tear starting

on the left side. From the looks of it, it has been there for quite

some

time. This frame was probably around 25 years old. |

|

Rear

dropout

with the mudguards mount nearly fallen off. The spotwelded protrusion

wasn't

meant to take a fully loaded rack |

|

This

is an

expensive frame but luckily with a guarantee*). The crack started on

the

left side in the heat-affected zone. The tear looks a bit oxidised, and

not as bright as the final crack on the right. Also note the cracks in

the clearcoat (picture on the left) which show that the tube has

deformed

as it broke.

*)

replaced

in a week

pictures

courtesy

Franke Nieuwenhuis

|

|

The

government

health surgeon has determined that pressing on regardless when the

chain

has caught between chainring and chainstay

is detrimental to your -aluminium- frame's life! Here's a

fatiguecrack

which not accidentally coincides with a deep dent. This won't last a

single

hard race. |

|

A

very thin

Tange Prestige doesn't like chainsuck at all either. Pity the painter

didn't

spot this before applying a thick coat of bondo. |

|

Another

crack

in an aluminium rear triangle. This one starts in the thick weld

attaching the bridge to the chainstay (dee insert)

|

|

Small

racing

accident, this is a cracked wishbone. The droplets are water, leaking

out

through the crack. Frame had to be replaced, the funny sized glued-in

wishbone

wasn't available: $$$$ ! |

|

Not

a bike

but it is Reynolds 531! This is a 40 year old subframe from a well-used

Jaguar E-type Cracks start around the stiffener/ suspension mounting

point. |

|

Again

a guaranteejob,

this time the toptube has started to part from the seattube on this

alumnium

MTB. The seattube is unaffected, which points to a defective weld. Too

short a seatpost (or a short adapter sleeve) (*) could give similar

problems,

but then the crack usually starts at the rear or from the sides.

(Photo

courtesy

Bert Lam)

(*)

Seat post

or sleeve should be inserted at least 2 cm below the toptube

|

|

Another

demonstration

of why loose non-welded seatclamps are popular. The stressconcentration

at the junction of the hefty lump to the thin walled tube in the heat

affected

zone was a bit to much.

Fixed

under

guarantee by welding up the crack, replacing the clamp with a

non-welded

version and repaint

(Photo

courtesy

Chris Leurs)

|

|

Rather

embarrasing

if this clamp breaks during a ride, but easily replaced with a sturdier

version with more meat where it counts |

|

Cracked

carbon

steerer. Probably due to insufficient support by the plug, I'd rather

see

a full tubular style here. But a fancy cutaway stem wasn't helpfull

either.

I try

to fit

stems on carbon steerers with a 5mm shim on top of the stem, which

should

move some of the clamping force away from the edge. |

|

See

here the

forkcrown of an only 5 holidays old Giant Expedition.The stiff

boxsections

of the crownhalves are welded to a flexible (thinwalled & large

diameter)

steerertube. This ensures that the welds are higly stressed. The

undercutting

(^) in the steerertube, where the weld goes round the corner

gives

this poor design the kiss of death. I would hate to ride this fork much

further, the fork will probably collapse if you have to make an

emergencystop. |

|

The

welder

has cut through the seatrail, creating a notch. This stressraiser does

as can be expected |

|

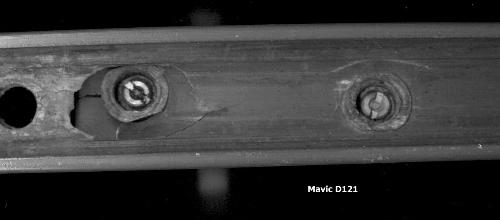

Double

eyeletted

Mavic which cried enough after 3000 km's. The rim stayed true

enough

to finish the trip but you can see straight through! Rim was advertized

as featuring 'bomb proof strenght' and a for best use of

'heavy

loads'. |

|

Another

cracked

rim, but you can't really blame it. Some cycleshop had managed to build

it with straight gauge #13 spokes (aka telegraph poles) at 150 kgs of

tension.

Massive overtensioned spokes without give do not build into a reliable

wheel. You'll never break a spoke again sir, indeed! |

|

And

yet another one

|

|

This

is a spokenipple

of a Mavic Ksiruim SSC rim. The nipple is threaded into the rim and

cannot

move. With a heavy sprinter the spoke will now have to bend at the

exit:

The nipple has cracked open and the aluminium spoke has sheared in

two |

|

Unless

you're

into watchrepairs I suggest you leave a STI shifter wll alone. No

spares

are available, so try to get a failed shifter warrantied first! Note

the

broken sintered? parts |