![[PT_header.jpg]](www.campagnolo.com/repository/tecnologie/testata/PT_header.jpg)

![[cbp5_bolt-hr14.jpg]](www.parktool.com/uploads/images/blog/repair_help/cbp5_bolt-hr14.jpg)

I have a great idea: instead of a heavy and unreliable seatpost clamp, you pick the seat height and we weld the seat in place.

Sound crazy? Campagnolo did something similar with their "Power Torque" cranks [Zi13]. (More on the cranks HERE as of 2013/07.)

![[PT_header.jpg]](www.campagnolo.com/repository/tecnologie/testata/PT_header.jpg)

![[cbp5_bolt-hr14.jpg]](www.parktool.com/uploads/images/blog/repair_help/cbp5_bolt-hr14.jpg)

Notably, Campagnolo introduced the cranks with no way to remove them.

Campagnolo Power Torque cranks install using a 14 mm hex (Allen) wrench that tightens a bolt threaded in one end of the spindle — generally similar to the installation of conventional square-taper cranks.

However, unlike square-taper cranks, there are no extractor threads. Further, Campagnolo apparently does not make tools to remove the cranks; and the "maintenance" section of the Campagnolo technical documentation (HERE as of 2013/07, COPY) does not mention removal.

Not that anything ever goes wrong during installation, not that anybody ever disassembles a bike for shipping, not that bearings ever need service, not that anybody ever wants to change crank arm length, not that cranks ever get damaged in accidents, not that anybody ever wants to switch to a triple crank, not that anybody ever wants to try their cranks on a different bike, not that... anybody at Campagnolo has any experience working on bicycles?

You can't take it off, but it can come loose. A 14 mm hex fixing bolt means carrying bigger/bulkier/heavier tools than field service tools for many other crank designs.

![[cbp5_bolt-hr14.jpg]](www.parktool.com/uploads/images/blog/repair_help/cbp5_bolt-hr14.jpg)

Many "mini" tool kits have a sleeve which is 8 mm hex on the outside and 6 mm hex on the inside. It should be straightforward to do something similar for 14 mm, but it is not obvious that something like that is for sale.

An intermediate solution might be a 14 mm bit such as this one with a 10 mm drive; and then a 10 mm box spanner.

![[s-l1600.jpg]](i.ebayimg.com/images/g/9BkAAOxyaTxRQMZG/s-l1600.jpg)

![[21_fot_012__39087.1509133962.500.750.jpg]](cdn11.bigcommerce.com/s-9t4wk8/products/22626/images/53797/21_fot_012__39087.1509133962.500.750.jpg)

Park tools now makes removal tools (HERE as of 2013/07.)

![[cbp5-fiberboard.jpg]](www.parktool.com/uploads/images/blog/repair_help/cbp5-fiberboard.jpg)

![[cpb5_mold-puller-plug-adjust.jpg]](www.parktool.com/uploads/images/blog/repair_help/cpb5_mold-puller-plug-adjust.jpg)

Note also the crank design requires a remover which "reaches around" the crank and thus is bulky and heavy compared to removers needed for other cranks, so for folks who travel and need to remove cranks, Power Torque cranks may be a poor choice.

Cyclus and VAR now also removers are smaller and lighter than the Park remover, but all are relatively bulky compared to conventional removers; as well, all are expensive compared to conventional removers.

![[33814_1_Cyclus_Abzieher-AdapterfUerCampagnoloPowerTorqueCarb.jpg]](static.bike-components.de/images/product_images/popup_images/33814_1_Cyclus_Abzieher-AdapterfUerCampagnoloPowerTorqueCarb.jpg)

![[1724471_1.jpg]](media1.roseversand.de/product/1850/1/7/1724471_1.jpg)

![[var-crank-extractor-for-campagnolo-power-torque-aluminum-crankset.jpg]](www.alibabike.com/18833-thickbox/var-crank-extractor-for-campagnolo-power-torque-aluminum-crankset.jpg)

Also, the Cyclus tools appear specific to the crank material, so if you have more than one Power Torque crank, you may need to buy multiple tools.

As of 2016/09 (and maybe earlier) Campagnolo offers UT-FC095, which appears to be an official piece of cardboard(?) that protects the crank during removal. It is not obvious what is the MSRP, but they were on offer on eBay for US$9 each or from an online retailer at Euros €11,90 for 5 (about US$2.50 each) plus shipping. Although Campagnolo offers corkscrews (about Euros €135), it is not obvious they offer a tool to remove the Power Torque crank. Just an official Campagnolo piece of cardboard, presumably to use with non-Campagnolo tools.

![[s-l1600.jpg]](i.ebayimg.com/images/g/C2gAAOSwa-dWosbN/s-l1600.jpg)

Starting 2015/08 and still up as of 2020/09, Park Tool has instructions "Crank Removal and Installation: Campagnolo® Power Torque™" [https://www.parktool.com/blog/repair-help/crank-removal-and-installation-campagnolo-power-torque]. The instructions describe the crank and then remark:

IMPORTANT NOTE: The Power Torque™ lacks any factory designed removal design or procedure. The Power Torque™ cranks are very difficult to grab and secure for a pulling operation. There will be [inherent] risk in servicing cranks of the Power Torque™ design.

The site describes two removal approaches. One is a "puller" approach as shown above. A second is to remove the bolt and insert the remover plug in the spindle, then hit the plug with a hammer.

![[CBP-8_001.jpg]](www.parktool.com/assets/img/product/CBP-8_001.jpg)

![[campy_crank_001.jpg]](www.parktool.com/assets/img/repairhelp/campy_crank_001.jpg)

![[campy_crank_002.jpg]](www.parktool.com/assets/img/repairhelp/campy_crank_002.jpg)

![[campy_crank_003.jpg]](www.parktool.com/assets/img/repairhelp/campy_crank_003.jpg)

![[campy_crank_0005.jpg]](www.parktool.com/assets/img/repairhelp/campy_crank_0005.jpg)

![[campy_crank_004.jpg]](www.parktool.com/assets/img/repairhelp/campy_crank_004.jpg)

It says this does not damage the bearings, because

The force is on the spindle and does not pass through the bearings [...]

It seems almost certain hammer force does pass through the left bearing: the hammer blow pushes the spindle to the right, the spindle pulls through the spline on the left arm, pulling the left arm also to the right. What keeps it from moving right? The inner race of the left bearing. What keeps the inner race of the left bearing from moving right? The bearings and the outer race.

That said, it probably does not damage the bearings, as the upper limit of the force is basically whatever pulls the spline out of engagement, which is probably below the static axial load limit of the bearing.

It seems likely that the same approach could be used but instead of a plug, screw in an old bolt; back it off a turn or two; then hit it with a hammer. It will damage the head of the bolt, but may be okay otherwise — aside from "inherent risk", above.

Hammers are relatively easy to come by compared to special tools, so carrying a spare bolt might be an effective way to do field/travel disassembly, but at lighter weight than carrying the full tool.

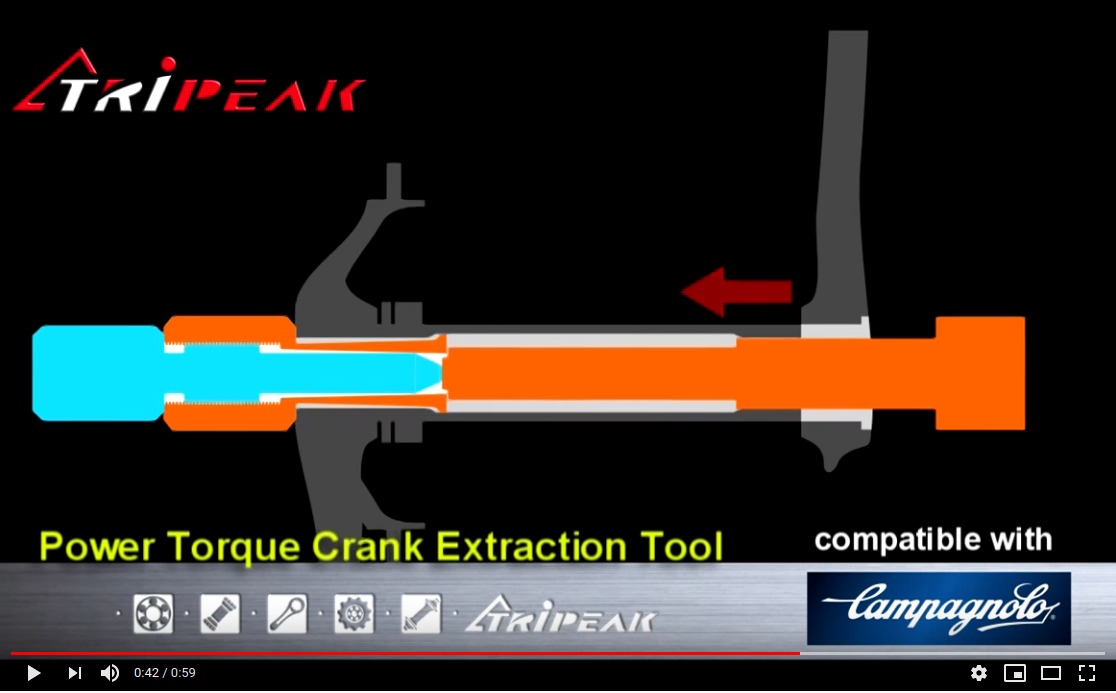

Starting 2013 and still as of 2020/09, TRiPEAK sells a Power Torque crank extractor.

![[maxresdefault.jpg]](i.ytimg.com/vi/UIGd5LHjgtE/maxresdefault.jpg)

![[Tripeak_Power_Torque_Extractor_Parent.wm.jpg]](sw6064.smartweb-static.com/upload_dir/pics/Tripeak/Vaerktoej/Tripeak_Power_Torque_Extractor_Parent.wm.jpg)

![[Tripeak_Power_Torque_Extractor_Parent_04.w610.h610.backdrop.wm.jpg]](sw6064.smartweb-static.com/upload_dir/pics/Tripeak/Vaerktoej/Tripeak_Power_Torque_Extractor_Parent_04.w610.h610.backdrop.wm.jpg)

One part of the tool looks like a standard hammer-type bearing extractor. It is inserted through the right crank and expands to fit on a shoulder in the inside diameter of the spindle. Then, instead of using a slide hammer, insert a rod through the spindle from the left, and hammer on the rod to drive the expanded extractor.

It is not clear what, if any, advantage there is over hammering on the Park extractor plug. The TRiPEAK tool may tend to somewhat retain the left arm, which otherwise may tend to fall to the floor. However, there is no secure connection between the "extractor" and "rod" portions, so no guarantee the crank will be retained.

As of 2020/09, Campagnolo offers the "UT-FC090 Power Torque Crank Extractor", which despite the "UT" prefix is for Power Torque cranks, and despite the lack of a Campagnolo name or logo on the tool appears to be a Campagnolo product.

![[Campagnolo-UT-FC090-Power-Torque-Crank-Extractor1462291275.jpg.jpg]](www.gbcycles.co.uk/images/product/Campagnolo-UT-FC090-Power-Torque-Crank-Extractor1462291275.jpg.jpg)

![[s-l1600.jpg]](i.ebayimg.com/images/g/a38AAOSwonBZ9uPb/s-l1600.jpg)

![[s-l1600.jpg]](i.ebayimg.com/images/g/OMQAAOSwBjdZ9uPf/s-l1600.jpg)

![[s-l1600.jpg]](i.ebayimg.com/images/g/8AIAAOSwytJZ9uPi/s-l1600.jpg)

It is not immediately obvious when this was introduced, although it appears there are web postings as far back as 2013, so within 2 years of the crank's introduction. Perhaps it was introduced at the same time as the crank and has been "hiding" unter the Ultra Torque "UT-" designation? Although it seems odd they would not at least mention it in the instructions nor was mentioned in publications of the day [Zi13].

It is unclear why there are two "plugs" in the kit. They appear to be identical, and one vendor says only one is "usually" required.

It appears the intended use is like the Park Tools "plug" and then use a gear puller, though be sure to use one where the "arms" are retained (like the Park Tools puller) and not free to spread, and slide off the crank.

And also be aware some gear pullers do not fit between the arm and the bottom bracket.

![[20121204162338.jpg]](cdn-ak.f.st-hatena.com/images/fotolife/h/hrrk/20121204/20121204162338.jpg)

![[20121204162453.jpg]](cdn-ak.f.st-hatena.com/images/fotolife/h/hrrk/20121204/20121204162453.jpg)

[Zi13] Lennard Zinn, How to remove Campagnolo Power Torque cranks, Velo News 2013/04/03. http://velonews.competitor.com/2013/04/bikes-and-tech/how-to-remove-campagnolo-power-torque-cranks_280400 as of 2013/07.