{body}

1985 Neoplan Cityliner

|

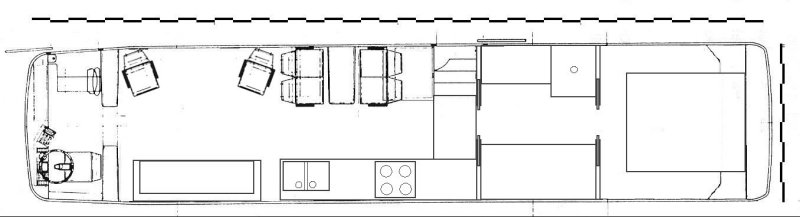

Our latest project is the conversion of a German made Neoplan Cityliner from a seated tour bus to a motorhome. The Neoplan N116/3 was manufactured in Stuttgart Germany, is 40' long and 8' wide and stands 11'6". As a touring bus it is equipped with a bathroom and seating for 53 passengers as well as a coffee bar and a hotdog cooker - only the Germans would build in a hotdog cooker! The bathroom will not suit the needs of a motorhome and is being modified, the seats are being removed and when finished it will have a bedroom in the rear with a queen size bed, a small office, two bunk beds, a full size shower, dinette, kitchen and a living room fitted with a sofabed and two chairs. >FLOORPLAN |

|

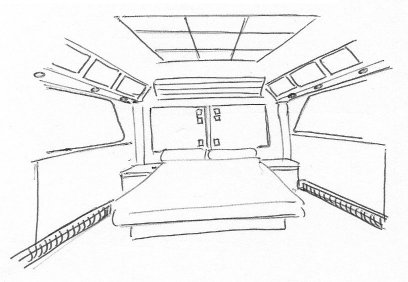

This drawing is the concept for the rear bedroom as seen from the dorway looking toward the rear of the bus |

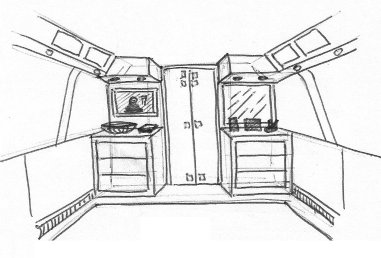

This drawing would be the view from the bed looking forward. |

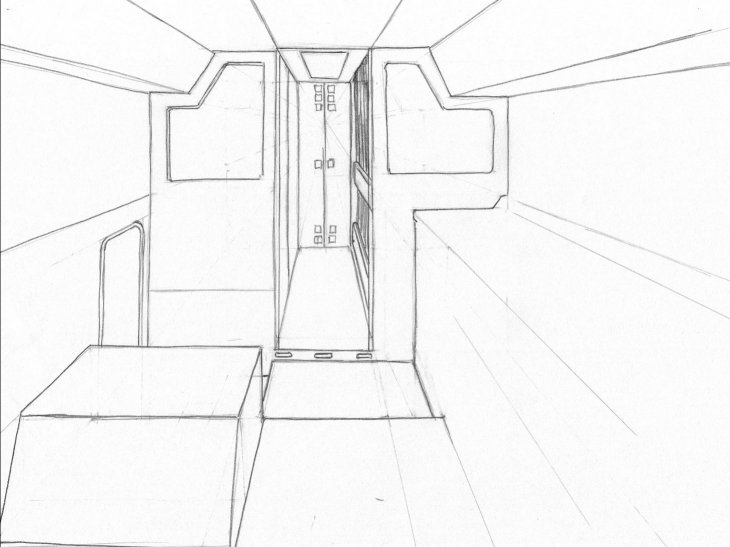

| Concept drawing - Interior looking reward, kitchen counter is on the right, dinette will back-up to the projection on the floor (left foreground) which is the top of the bathroom - accessed by walking down the rear stairs. Past the bulkhead fitted with pocket doors (open in drawing) are bunks on the right, a desk and shower stall on the left. Pocket doors to the bedroom are closed in this drawing. |

Trimetric views click to enlarge |

Factory drawings click to enlarge |

Conversion of engine fuel system to burn Recycled Vegatable Oil

|

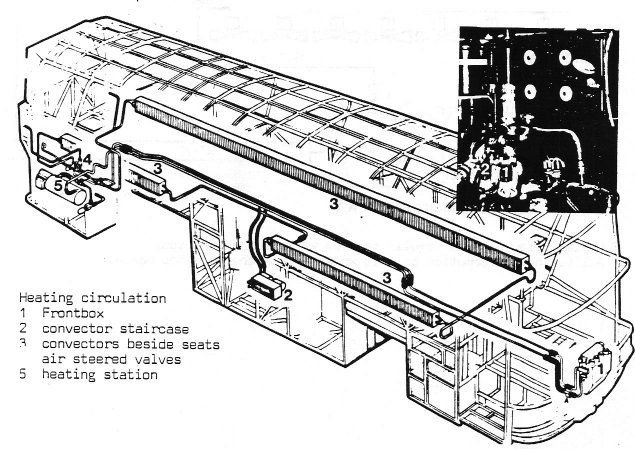

The diesel engine was originally designed to burn vegatable oil, I will not go into the\is in detail as the modern Diesel is a completely different animal and mention this only as an interesting footnote. Diesel engine manuals have a section of fuels which can be burned in an emergency, these include heating oil, vegatable oil, karosene, solvents, etc. The fact is Diesels will burn just about and oil, some less effeciently than others and some if used for an extended perion will damage the engine. Here we are dealing with the combustion of waste vegatable oil (WVO) which is what is in the barrels behind any restauraunt which frys food. Typically this is a very high grade oil which has been contaminated by cooked foods to the point where it will begin to impart flavors to the food cooked in it, it is then disposed of and usually reprocessed and used in the manufacture of soaps, cosmetics and animal feed. The simple science is as follows: Diesel fuel has a viscosity of 10-15 centistrokes, you really don't need to know what a centistroke is, just that it is how viscosity is measured. WVO when heated to 80C has a viscosity of about 9 centistrokes and can then be burned just as efficiently as Diesel fuel with little or no detrement to performance and none to engine longevity. The other considerations of burning WVO are as follows: Damage to injectors due to coking - No factual evidence has ever been produced showing that burning heated WVO causes any increase in coking. ( An associate of mine had injectors removed from a Detroit Diesel with 100k+ miles which show no signs of abnormal coking) Damage to the injectors due to heat - Diesel injectors are cooled by the fuel passing through them and some have suggested that running heated fuel could cause injector damage - again with no evidence. The injectors are mounted in the head itself and the difference in fuel temp between an unheated system and a heated system woul average less than 80F, considering the heat transfer from the engine, 80F is not enough difference to consider. QAgain no one has ever actually had an injector damaged and the concept of such damage is weak on sicence. Damage to injection pumps - Again no evidence has ever been produced. WVO becomming a semi-solid at low temperatures - In the system we are using the fuel is heated in the tank using engine coolant, the lines are heated as well. System design: The engine will be started burning conventional diesel fuel, once the engine is warmed to temperature and electric solonoid valve will switch the fuel supply and return lines from the diesel tank to the WVO tank and the system will burn WVO. 7 to 10 minutes before the engine is shut down for any period longer than one hour, the valve will be switched to diesel allowing the diesel to displacec any WVO in the injection system. (this is done to insure that should the engine temp drop to less than 22C {70F} WVO will not solidify in the system). The stock 144 gallon fuel tank will be modified by welding a 1/2" deep sealed pan to the bottom of the fuel tank, engine coolant will pass through this pan and heat the fuel tank itself to the same temperature as the coolant which is 80C. The WVO will then travel through lines, bundled with coolant fed lines, from the tank to the solonoid valve and into the injection pump. Fortunately Neoplan busses are fitted from the factory with 1" copper coolant lines supplying the internal hydromic heating system, these lines run along the roof of the cargo bays, just above the fuel tank, from the front of the bus to the rear. In addition Neoplan Busses are fitted with a diesel fired hot water heater to heat the interior and preheat the motor in cold weather. The WVO lines will be bundled along this existing coolant line and enclosed in standard pipe insulation. An additional 50 f\gallon fuel tank will be installed for the diesel fuel. |

|

Utilizing this system, the engine will only run on Diesel fuel during start up and shut down, perhaps 10 minutes each time the vehicle is driven, the remainder of the time it will be running on WVO...which is free. WVO supply: Typically WVO is stored in barrels behind restauraunts and they contract a company to dispose of this oil for them and pay for this service. I have contacted several businesses in my area and all have been very interested and have without fail given me permission to collect as much of the oil as I like. As an experiment I plotted a trip from Seattle to LA and using a road guide located restauraunts along the route. I called these businesses and told them of my hypothetical travel plans and my need for waste oil, all offered as much as I could take away. Once a source is located the bus will be pulled up as close as possible to the storage tanks, a line will be run from the tank to the bus and a pump will suck the oil into a heated storage tank, another pump will force the heated oil through a series of filters ending with a .5 micron filter and then into the main tank. This process will function at about 3 gallons per minute. Pumping and filtering 50 gallons of WVO should take less than 20 minutes. In addition I am building a filter and storage system in my shop. This will consist of an electric home water heater with the top cut off, a pump and series of filters and a tap under which 55 gallon drums can be placed. Once filled they will be stored for future use. As a footnote: When researching this concept many bus owners have said "Do what you want but I am not risking my expensive engine with experiments" To those persons I say "I will do just that, no evidence exists showing that any damage results from this system, even with many such conversions having been driven in excess of 100k in this country and many more in Europe - this is not a new concept, only new in the US. For me the idea of travelling without paying $2.00+ a gallon at 8mpg is too good to pass up." |