Technology

| Quote from "Weight Weenie" and "mobile01" related disscussion | ||||||||||||||||

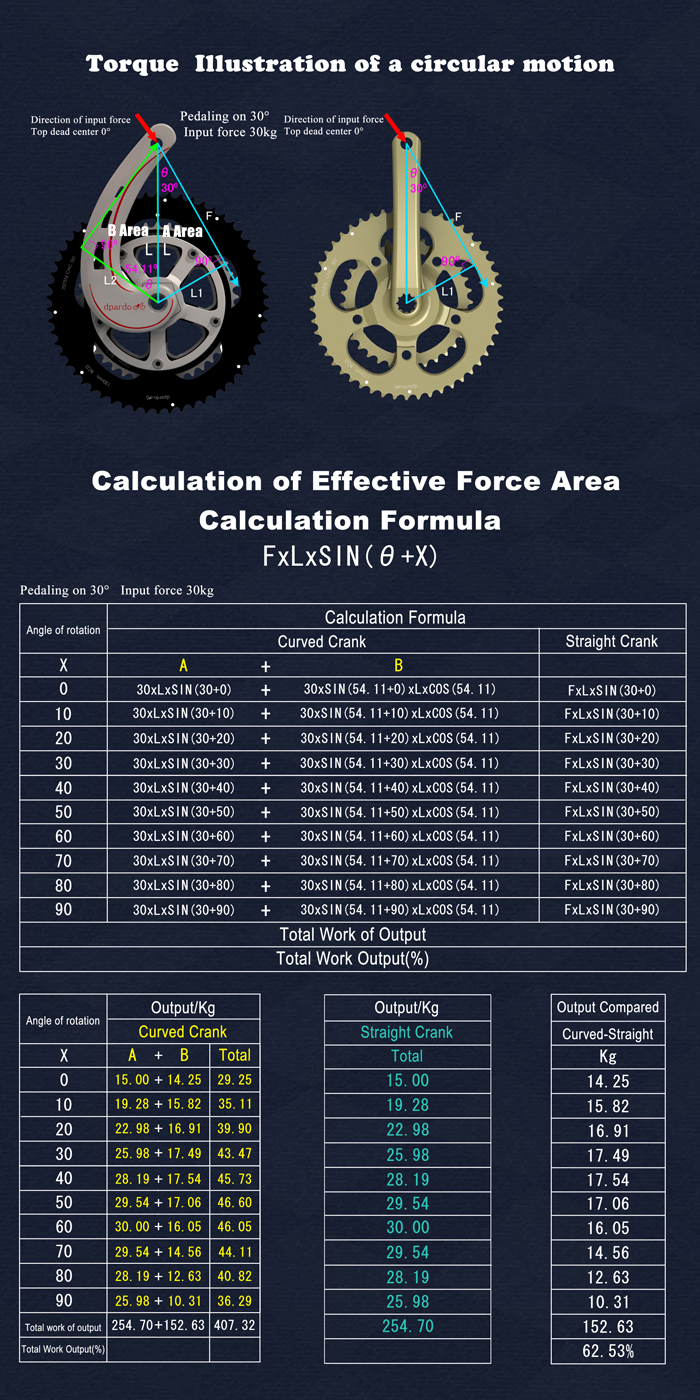

Those have opposition or think lever theory about curved cranks, if their viewpoint is correct, why people so surprise curved crank's efficiency after riding. As I know the efficiency comes from the gravity of cranks forward , in other words, toe-out effect. The calculation formula is not using lever theory but using trigonometric function to calculate its effective force area. According to maker' data, they did integral calculation by every 10 degree then total work got 33% efficiency that is compared with traditional straight crank. On upper dead point , straight crank is vertical to axle ,so most of pedaling force are lost on this angle. However sickle crank not only center gravity forward but also effectively pass through upper dead point and reduce loss, so output increases by 33% compared with straight crank.. |

||||||||||||||||

|

||||||||||||||||

| There are two kinds of scientist since long time ago- practice and laboratory scientists. Science calculation is to explain nature phenomenon not simply to examine its possibility. The sickle crank's efficiency is fact and proved. It is said that SGS was surprised, too when they got result. The follows comes from official website |

||||||||||||||||

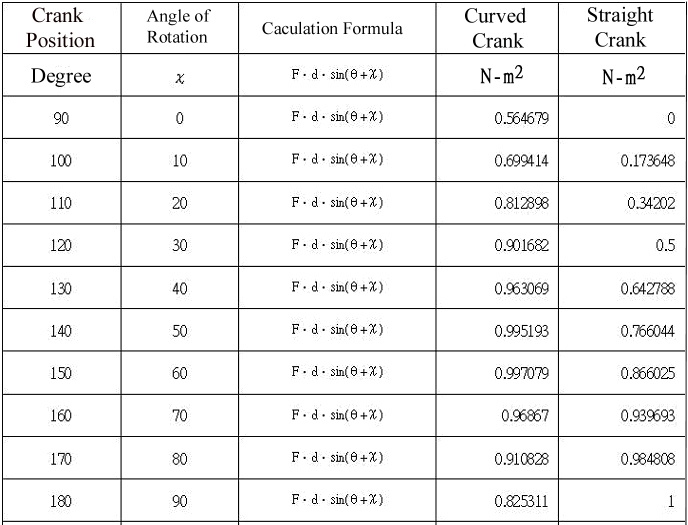

| 1. calculation formula( by every 10 degree) | ||||||||||||||||

|

||||||||||||||||

| According to this data you can see torque output is bigger than straight crank before 160 degree and get more efficiency from 0 ~130 degree. Reduced force loss in the max pedaling force losing zone , so curved crank can get more torque output. Straight crank is better than curved from 160~180 degree , however, it is in the low pedaling force losing zone ,besides on 180 degree position , the other crank already on the 0 degree(upper dead point) to start new circulation . If using clipless pedal to pull from low dead point , the efficiency will be as same as 0~130 degree. One leg pedal and the other leg pull by clipless pedal , it will get multiple effect. |

||||||||||||||||

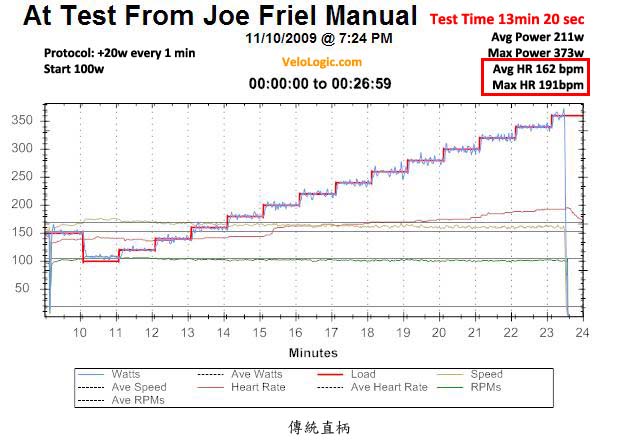

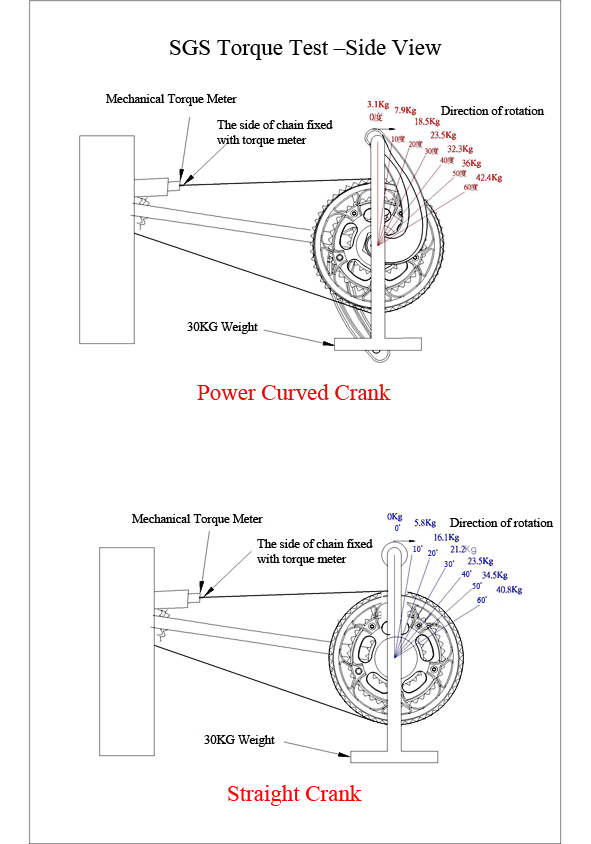

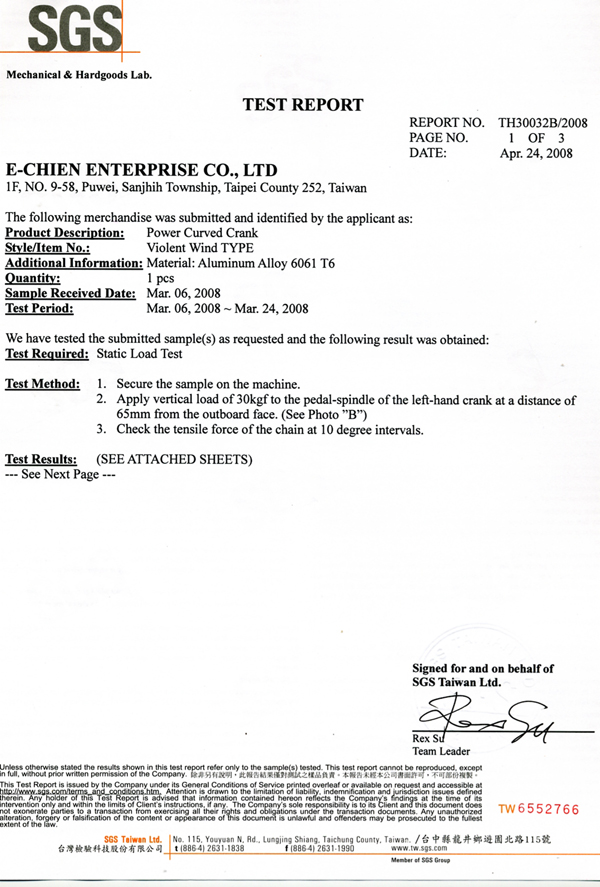

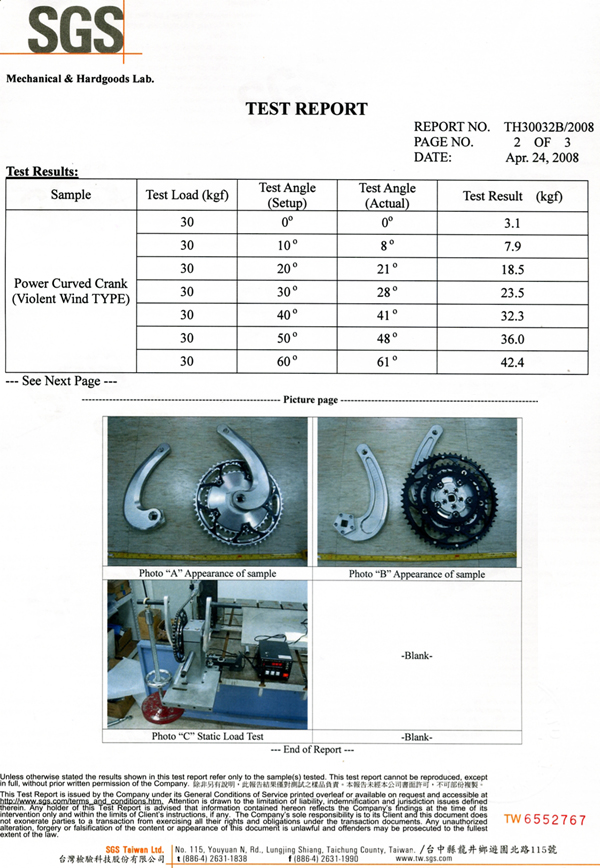

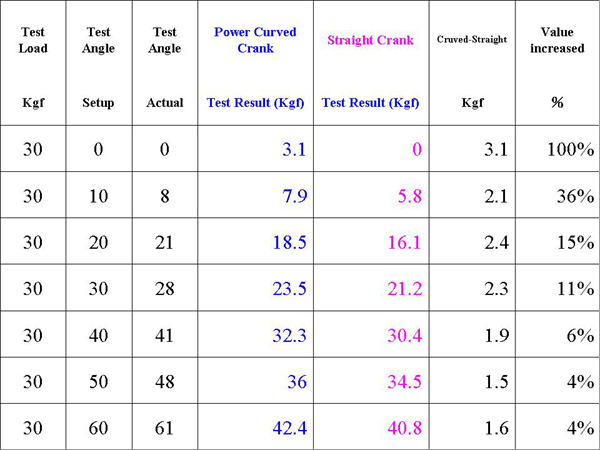

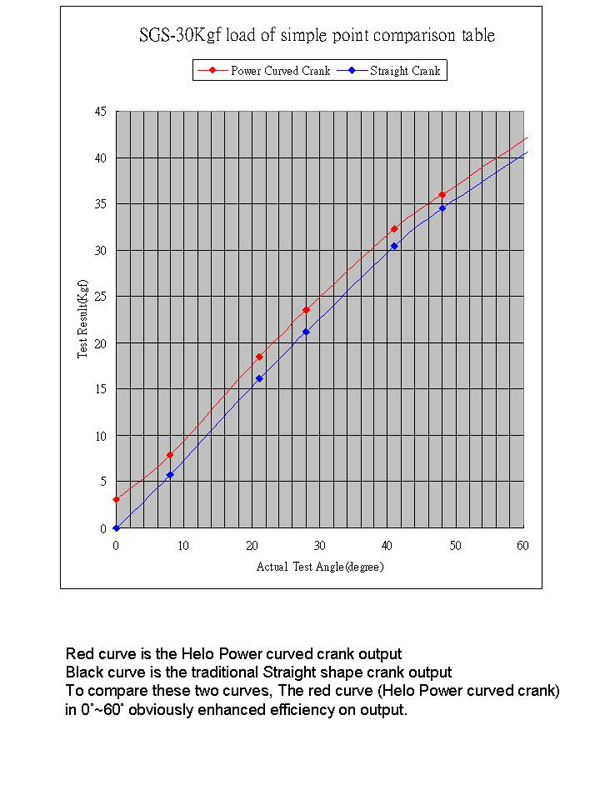

2.SGSTest report

More energy can be released for works due to the obvious improvement on the applied force in the effort-demanding zone between the dead - point and the 60-degree angle. The figure below reports the SGS torque comparisons for all separate angles incremented by 10 degrees.

|

||||||||||||||||

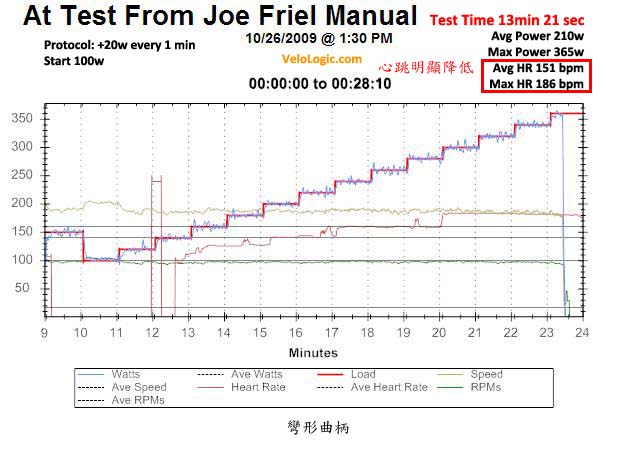

| 3. USA Cyclist used computer trainer to test, AVE HR reduced 11 bpm,maximal oxygen consumption reduced 9%;MAX HR reduced 5 bpm,maximal oxygen consumption reduced 4% | ||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

| I installed one set. When pedal harder , I could feel the explosive power form rear wheel .If I constant speed ride , the pedal seems be driven by certain force and automatically pass through upped dead point. Some one had pedaled 53t gear and his rpm increased 20%. My experience is using front 56t and rear 11t , feel as same as 50 t gear. The speed is very fast and easy to reach 40km/h, well, because it is 56t. Some friends got good physical condition they could easy to reach 50~55km/h One of my riding course is 20km and 9.75km is a slope. The slope is average 3.5% and last 2km is 7.5% slope. It took 90 minutes to run this course, but used this sickle crank , it only takes 70 minutes. 20% faster. My good friend , a bicycle shop owner, he remodeled his MTB with sickle crank and 700C wheel to compared with his original road bike with straight crank. The former uses front 42t - rear 15t and the latter used 39-15, he said the former is much easier to pedal, pedaled 3 times rpm gone 60 , pedaled 5 times rpm gone 90,so it could save a half time to reach the latter's rpm From these riding experience , I know it really get efficiency |

||||||||||||||||

| Illustration of mechanical torque test machine(not digital type) |

|

|

SGS Test Report

More energy can be released for works due to the obvious improvement on the applied force in the effort-demanding zone between the dead - point and the 60-degree angle. The figure below reports the SGS torque comparisons for all separate angles incremented by 10 degrees.

| Power Curved Crank | |

|---|---|

|

|

|

|

| Traditional Straight Crank | |

|

|

|

|

Crank driving performance analysis excepert from Academic units Report

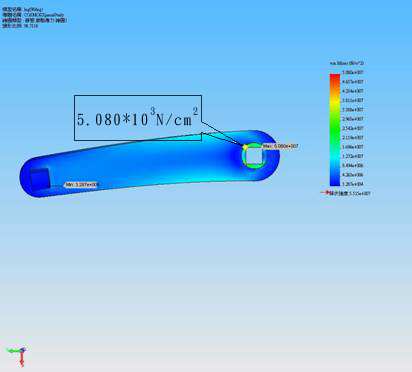

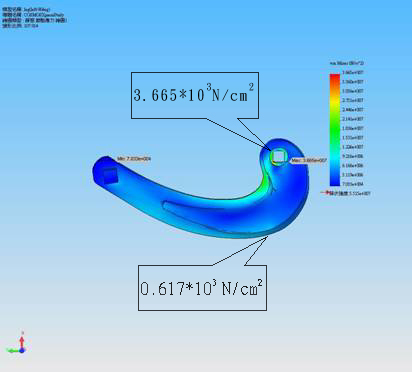

Stress Analysis

|

|

|---|---|

|

|

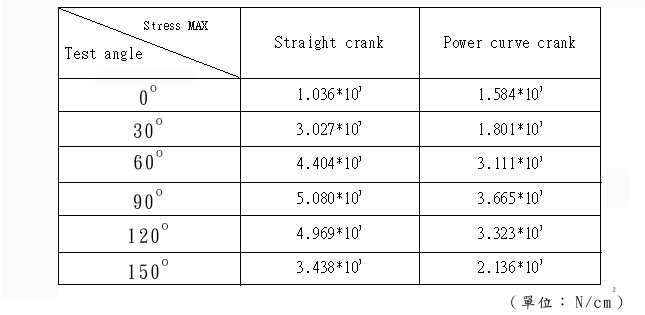

| List-Stress comparison | |

|---|---|

|

|

From the results above, the most stress is located at the fixed joined of the rotation axle by riding on the straight type crank that is similar as the cantilever beam structural. Therefore, the straight type crank has the stress located at inner part of the fixed joined of the rotation axle. |

SGS Power Curved Crank Fatigue Test Report

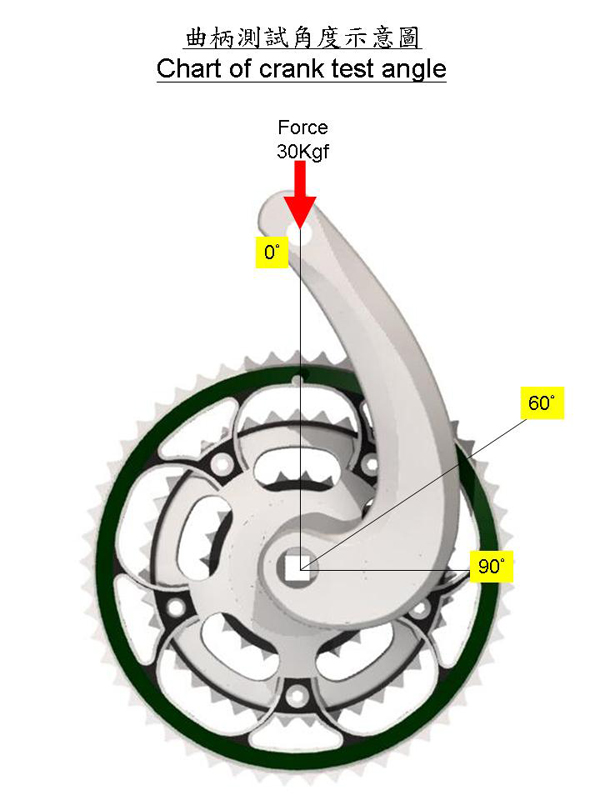

| The power forward effect of power curved crank(golden spiral and toe-out on turns) is increasing |

| thetorque output from 25% to 30% between 0°-60°. |

| Even on Upper Dead Center(0°), it has 3KG torque output when imposing 30KG pedaling force. |

| Therefore, in order to support powerful torque output and the need of structure, the total weight |

| of our crank is 900 g. |

| We insist the efficiency、stifffness and durability are more important than light weight bicycle |

Imposing 180KG pedaling force on 30° in 50,000 times fatigue test,the BB borked on the |

|---|

25,000th time. |

The following pictures are the cranks and BB after the test. |

|

|

|---|---|

|

|

|

|

|

|

| Power Curved Crank AL 7075 T6 Test Report |

|---|

|

|

|

Power Curved Crank AL 6061 T6 Test Report |

|

|

|

Calculation formula(The calculation was using trigonometric function to calculate its effective force area then did integral calculation by every 10 degree to calculate total work)

|

| According to this data you can see torque output is bigger than straight crank before 160 degree and get more efficiency from 0 ~130 degree. Reduced force loss in the max pedaling force losing zone , so curved crank can get more torque output. Straight crank is better than curved from 160~180 degree , however, it is in the low pedaling force losing zone ,besides on 180 degree position , the other crank already on the 0 degree(upper dead point) to start new circulation . If using clipless pedal to pull from low dead point , the efficiency will be as same as 0~130 degree. One leg pedal and the other leg pull by clipless pedal , it will get multiple effect. |